| << Chapter < Page | Chapter >> Page > |

6.4.8 Comments on Solid State Diffusion:

After etching out the SiO 2 mask, the wafers are put in central flat zone of the diffusion furnace shown in Figure 6.14 where temperature is maintained between 800 o c to 1200 o c and inert gas (carrier gas) carrying the impurity compound vapour is passed through the furnace. The compound reacts with Si, releasing the dopant. The dopant atoms, dissolved in solid phase of Si, ionize and occupy the substitutional positions in the Si lattice (i.e. the positions of host atoms). The maximum surface concentration of the dopant is No which is determined by the solid solubility of the given dopant into Si.

6.4.8.1 Constant Source Diffusion (pre-deposition)

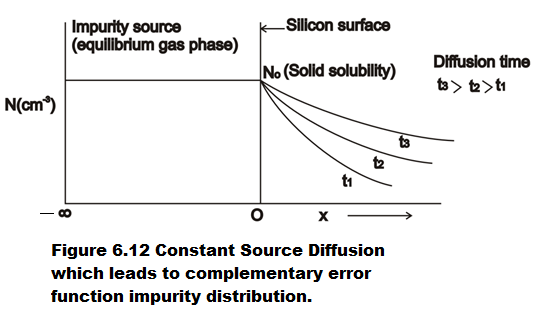

As long as the partial pressure of impurity compound is maintained at a constant level, the surface concentration is maintained at Ns. The impurity atoms diffuse from the surface to the interior of the wafer resulting in a given impurity profile. The boundary condition in which diffusion is carried out with surface concentration of dopant held constant is known as constant source diffusion and this results in complementary error function (erfc) distribution of the impurity in the wafer as shown in Fig.(6.12).

(dopant profile) N(x) = N

s erfc

Where D=diffusion constant of the dopant

t = diffusion time

N s =surface concentration of the impurity.

This constant source deposition is known as pre-deposition. Pre-deposition is carried out with partial pressure of impurity compound high enough so that N s =N o (i.e. surface concentration in the wafer corresponds to solid solubility of the impurity in Si). Pre-deposition is carried out in cases where high doping concentration and shallow diffusion is desired.

6.4.8.2 Limited Source Diffusion (Drive-in)

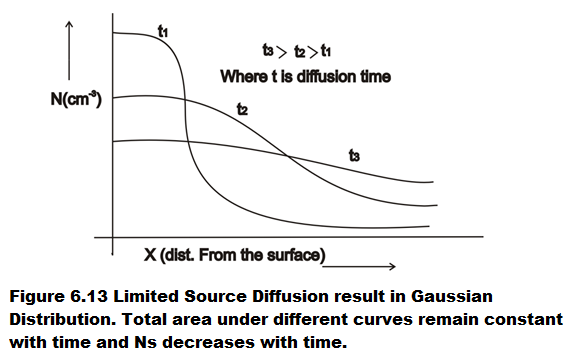

For achieving lighter and deeper diffusion limited source diffusion is resorted to. In limited source diffusion, first through pre-deposition, a layer of impurities are deposited on the surface of the wafer. Suppose total number of impurities deposited is Q. Subsequently in an oxidizing ambient, at high temperature, the final diffusion is carried out. Here the oxidizing ambient forms SiO 2 which seals the impurities in the wafer and fixed quantity of impurities, Q, constitutes the limited source of dopant from which dopants diffuse deeper into the wafer .Hence this is called limited source diffusion or drive in and this results in Gaussian distribution of impurities in the wafer. The Gaussian dopant profile is given by the expression below and shown in Fig.(6.13):

N(x) = Q/

Where Q = total number of impurities on the surface of the wafer at the start of drive in.

Limited Source Diffusion is also known as Drive in Diffusion. This is done where low surface concentration and deeper diffusion is desired.

The diffusion depth of dopant, which is a fraction of micron to about 10 µm, very critically depends on temperature and time.

Since D=D

0 exp

D 0 , R are constants;

∆H = activation energy for the diffusion of an impurity,

T = temperature in K.

Notification Switch

Would you like to follow the 'Solid state physics and devices-the harbinger of third wave of civilization' conversation and receive update notifications?