| << Chapter < Page | Chapter >> Page > |

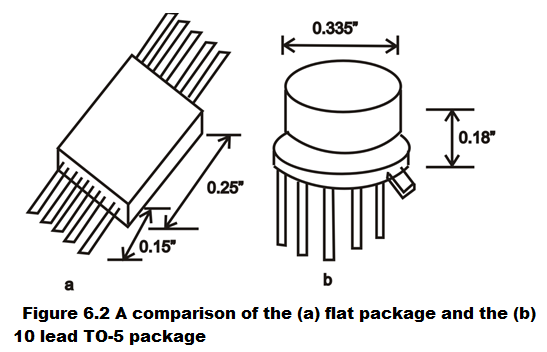

Two basics packages currently in wide use for I.C.’s are : new flat package and other is a multileaded TO-5 package . Flat packs can be mounted on both sides of a printed-circuit board whereas TO-5 packages can be mounted only on one side of PCB because of their plug in nature. Flat package gives advantages in compactness of 5 or 6 to 1. The two are illustrated in Fig.(6.2)

The six steps of Epitaxial Diffusion process will be briefly described and illustrated by actually going through the fabrication steps of MC 1530, the first generation of high performance operational amplifier marketed by MOTOROLA in mid-60’s.

The heart of Epitaxial Diffusion is the basic masking technique (or photolithography) which enables the selective impurity diffusion or ion implantation into silicon wafer and which enables to achieve a definite pattern of Aluminum interconnections according to the circuit requirement.

6.3.3 Photolithography:

To fabricate a complete integrated circuit a set of photo masks are used in sequence. Each photo mask has a pattern according to the specific requirement of the step in which it is going to be used. Furthermore the image produced by each mask must properly align with the image of the preceding mask so that the sum total effect of all the masks results into the desired circuit.

Photo mask fabrication consists of the following steps:

The first artwork is prepared 200(×) the actual integrated circuit layout. This makes the preparation of the artwork convenient as well as accurate. The master artwork is cut on Rubylith by coordinatograph. Rubylith is Mylar laminate with a pealable opaque overlay. By cutting the overlay with a knife edge it may be removed to form clear areas in an opaque background.

Once the initial artwork is prepared, the single image is reduced 20:1. This first reduction image must be an extremely accurate reproduction of the master artwork therefore the photography should be sharp.

By a step and repeat camera, the first reduction image is contact printed at a point and then moved from that point to another point at an accurate spacing. This multiple printing continues until the desired array is achieved. By multiple-lens camera also this multiple array of images can be achieved.

The multiple images formed are then reduced to the final desired size by producing a microphotograph of the print from the step-and-repeat machine. The final reduction is 10:1 and sharpness of focusing has to be maintained.

There is nothing sacrosanct about the 200(×) magnification of the master artwork and 20:1 first reduction and 10:1 second reduction. There are many considerations which decide the magnification and the reduction ratio. Also the sequence of steps described above is not strictly followed in preparation of photo masks. The formation of multiple images may precede, coincide with or follow the final image reduction.

The set of photo masks required for the fabrication of MC 1530 are:

Notification Switch

Would you like to follow the 'Solid state physics and devices-the harbinger of third wave of civilization' conversation and receive update notifications?