| << Chapter < Page | Chapter >> Page > |

Phase transfer catalyzed reaction has been used for piezoelectric polymer preparation from malonitrile, however this method leads to low molecular weight, and low yield of impure vinylidene cyanide units containing material. The use of solid K 2 CO 3 and acetonitrile without added phase transfer catalyst shows excellent yields for polyester possessing backbone gem-dinitriles and for polyamide synthesis. The polyester and polyamide obtained contained a dinitrile group net dipole which can be align in the same direction as the carbonyl groups.

The pursuit for better piezoelectric polymers has led to molecular modeling which indicates that one cyano substituent should be almost as effective as two geminal cyano substituents, opening a new area of potential materials having an acrylonitrile group as the basic building block. However, polyacrilonitrile itself is not suitable because it forms a helix. Thus acrylonitrile copolymers have been investigated.

Most of the piezoelectric polymers available are still synthesized by conventional methods such as polycondensation and radical polymerization. Therefore piezoelectric polymer synthesis has the same problems as the commercial polymer preparation, such as controlling the degree of polymerization and crystallinity.

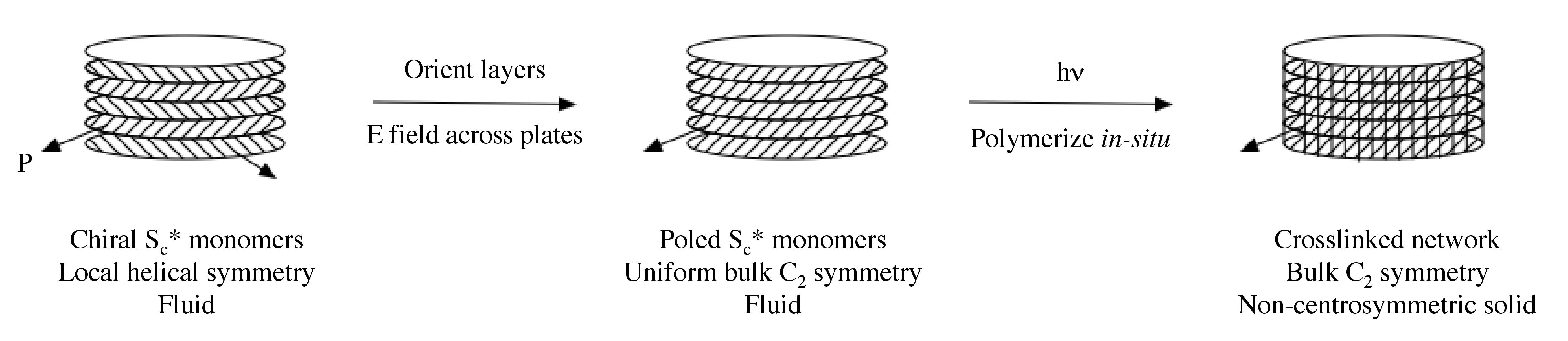

A novel technique of vapor deposition polymerization has been reported as an alternative method to copolymeric thin films. Aliphatic polyurea 9 was synthesized by evaporating monomers of 1,9-diaminononano and 1,9-diisocyanatononano onto glass substrate in vacuum. Deposition rates were improved at temperatures below 0 o C. After poling treatment films showed fairly large piezoelectric activities. Additionally, a completely novel approach to piezoelectric polymers has been presented. This approach, consists in the synthesis of ordered piezoelectric polymer networks via crosslinking of liquid-crystalline monomers. The main goal in this approach is to achieve a polymer network which combines the long term stability of piezoelectric single-crystals with the ease of processability and fabrication of conventional polymers. [link] shows the schematic representation of this approach.

Piezoelectric polymers are becoming increasingly important commercially because of their easier processability, lower cost, and higher impact resistance than ceramics, but the lack of high temperature stability and the absence of a solid understanding of the molecular level basis for the electrical properties are limitations. The requirements for strong piezoelectricity in a polymer are: the polymer chain has a larger resultant dipole moment normal to the chain axis; polymer crystallizes into a polar crystal with the polar axis perpendicular to the chain axis, has a high crystallinity and finally the polymer polar axis aligns easily in the thickness direction during poling.

Piezocomposites have been obtained by the combination of piezoelectric ceramics and polymers, the resulting material posses both the high piezoelectric properties of ceramics and the processability of polymers. 1-3 type piezocomposites have found wide applications as medical and industrial ultrasonic transducers.

Notification Switch

Would you like to follow the 'Chemistry of electronic materials' conversation and receive update notifications?